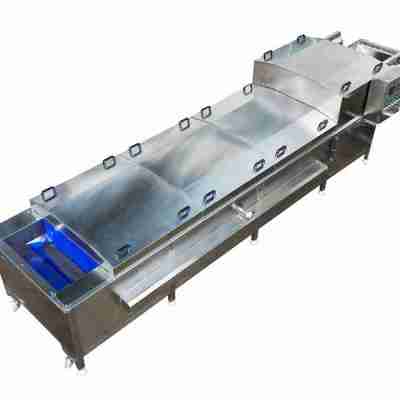

Blanching Machine

Published By VER Food Solutions

- Location: United States

- Status: In stock

The blanching machine operates using electricity or steam as its energy source. It is designed and manufactured based on thermodynamic principles and specific food requirements, allowing it to blanch products of various specifications. The blanching time and temperature are automatically controlled, ensuring a simple and safe process that conserves both water and energy. The primary goal of the blanching machine is to preserve the vibrant color of fruits and vegetables by deactivating enzymes that can affect their freshness.

Additionally, blanching helps to eliminate any odors, tightens the internal structure of the materials, and prevent the loss of aromas from marinated items. The process utilizes hot water, with electric or steam heating as the primary methods. Steam heating is commonly preferred for long-term use due to its cost-effectiveness. The operation is fully mechanized, eliminating the need for manual labor. Materials are transported into the blanching machine via a conveyor belt, equipped with frequency control to adjust the blanching time according to different product requirements. After blanching, the products are directed through a powerful air dryer, which removes any residual moisture from their surfaces, reducing the need for manual drying and increasing operational efficiency for the enterprise.

INTERESTING?? Call +86-18866883278 or visit VER Food for Solutions Blanching Machine PRICE NOW! or visit: https://www.verfoodsolutions.c....om/products/vegetabl