Understanding the Dynamics of the Refractory Material Market

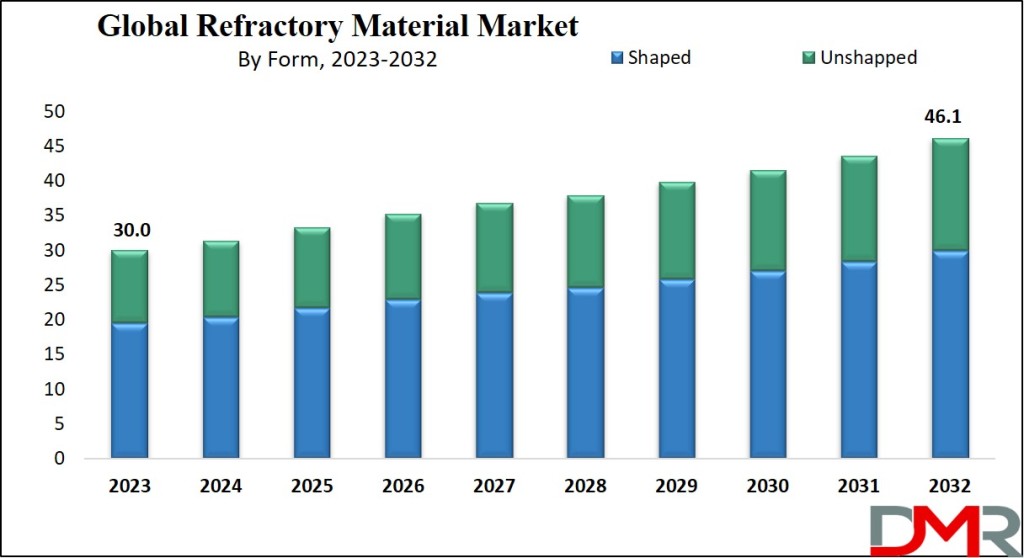

In the realm of industrial operations, refractory materials serve as the unsung heroes, quietly facilitating processes across various sectors with their remarkable resilience and durability. As advanced ceramic substances, they are meticulously engineered to withstand harsh conditions including extreme temperatures, chemical corrosion, and mechanical stress. The Global Refractory Material Market, valued at an impressive USD 30.0 billion in 2023, is poised for further growth, projected to soar at a robust 4.9% CAGR through the forecast period spanning from 2023 to 2032.

Get a Free PDF Sample Copy of This Report@ https://dimensionmarketresearch.com/report/refractory-material-market/request-sample

The Crucial Role of Refractory Materials

Refractory materials play an indispensable role in numerous industries, underpinning critical manufacturing processes in sectors ranging from iron and steel to cement, metals, glass, paper, pulp, and petrochemicals. Despite often operating behind the scenes, these materials are essential components, ensuring mechanical durability, resistance to corrosion, and effective thermal insulation. In sectors like steel production, refractory materials are treated as consumables necessitating periodic replacement, whereas in industries such as glass and cement, they are viewed as long-term investments, with the potential to serve for up to a decade.

Impact of Market Dynamics

Market Dynamics

The growth trajectory of the Global Refractory Material Market is intricately linked to the dynamics of various industries, with investments in the iron and steel sectors emerging as a significant driving force. Nations like the United States, China, and India are witnessing a surge in iron and steel production, propelled by rapid infrastructure development and heightened demand from sectors such as automotive manufacturing.

Ecological Considerations

While refractory materials contribute significantly to industrial progress, their ecological impact cannot be overlooked. The raw materials used in their production, including carbon, carbides, silica, and ceramic fibers, pose environmental challenges. Prolonged exposure to ceramic fibers, for instance, can lead to respiratory issues and skin irritation. Moreover, the manufacturing process itself emits hazardous pollutants, underscoring the importance of sustainable practices and eco-friendly alternatives.

Research Scope and Analysis

Form and Product Segmentation

Shaped refractory materials, characterized by intricate designs and larger surface areas, dominate the market landscape, particularly in industries requiring superior thermal insulation solutions. Meanwhile, the clay segment commands a larger market share owing to its cost-effectiveness and widespread usage in products such as fireclay bricks and insulation materials. In contrast, non-clay refractory products boast superior corrosion resistance, making them indispensable in environments exposed to strong acids and bases.

Alkalinity and End-User Analysis

Within the alkalinity segment, basic refractory materials hold sway, finding extensive application in environments with alkaline conditions such as incinerators and chemical manufacturing facilities. In terms of end-users, the iron and steel sector emerges as the dominant force, driving substantial demand for refractory materials across furnaces, reactors, and vessels. The glass industry, propelled by a shift towards eco-friendly alternatives, also contributes significantly to market growth.

Recent Developments in the Refractory Material Market (2023-2024)

- The global Refractory Material market size was valued at USD 27.26 billion in 2022 and is predicted to reach USD 42.41 billion by 2032, growing at a CAGR of 4.5%.

- The market is expected to see moderate growth due to factors like increasing applications, technological advancements, and rising demand in Asia Pacific and Europe.

Buy This Report Here@ https://dimensionmarketresearch.com/checkout/refractory-material-market

Key Takeaways:

- The Global Refractory Material Market is projected to reach a valuation of USD 30.0 billion by 2023, with a 4.9% CAGR anticipated till 2032.

- Refractory materials are essential in industries such as iron and steel, cement, glass, and petrochemicals, providing crucial thermal insulation and corrosion resistance.

- Asia-Pacific dominates the market, driven by rising demand for iron and steel in sectors like construction and automotive manufacturing.

- Despite their industrial importance, refractory materials pose ecological challenges due to the raw materials used and the manufacturing process.

Regional Outlook

Asia-Pacific emerges as a powerhouse in the refractory material market, commanding a lion's share of 82.3% in 2023. The region's dominance is fueled by the burgeoning demand for iron and steel, particularly in construction, automotive, and industrial sectors. China, in particular, stands out with its rapid expansion in the cement manufacturing sector, necessitating high-quality refractory products tailored for high-temperature applications.

Key Players and Competitive Landscape

In this dynamic market landscape, several key players vie for prominence, including Imerys, Saint-Gobain, RHI Magnesita, and KAEFER SE & Co. KG, among others. These industry stalwarts leverage innovation and strategic partnerships to maintain their competitive edge and cater to the evolving needs of diverse end-users.

FAQs

1. What are refractory materials, and what role do they play in industries?

Refractory materials are advanced ceramic substances designed to withstand harsh conditions such as high temperatures, chemical corrosion, and mechanical stress. They play a crucial role in facilitating manufacturing processes across various industries by ensuring mechanical durability, resistance to corrosion, and effective thermal insulation.

2. Which sectors drive the demand for refractory materials?

The demand for refractory materials is primarily driven by sectors such as iron and steel, cement, glass, non-ferrous metals, and petrochemicals. Among these, the iron and steel sector commands the largest share due to its extensive usage of refractory materials in furnaces, reactors, and vessels.

3. What are the ecological considerations associated with refractory materials?

While refractory materials contribute to industrial progress, they also pose ecological challenges. The raw materials used in their production, including carbon, silica, and ceramic fibers, can have adverse effects on the environment and human health. Additionally, the manufacturing process emits hazardous pollutants, necessitating sustainable practices and eco-friendly alternatives.

4. Which regions exhibit significant growth potential in the refractory material market?

The Asia-Pacific region, particularly countries like China and India, holds immense growth potential in the refractory material market. The region's rapid industrialization, coupled with robust infrastructure development, drives demand for refractory materials in sectors such as iron and steel, cement, and automotive manufacturing.

5. How do key players differentiate themselves in the competitive landscape?

Key players in the refractory material market differentiate themselves through innovation, strategic partnerships, and a focus on sustainability. By leveraging advanced technologies and forging alliances with industry stakeholders, these players strive to meet the evolving needs of diverse end-users while maintaining a competitive edge in the market.